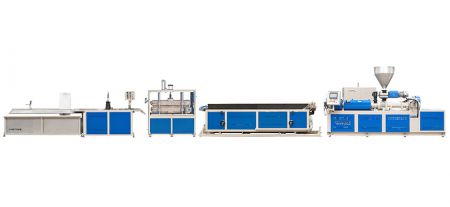

Twin Screw Profile Extrusion Line

PEW

For high performance and efficiency, INTYPE develop twin-Screw extruders, especially suitable for powder type material manufacturing.

Resin : PVC, PP, PE, PS, ABS, PC, PET, Foam Plastic, TPE....

Characteristic of the Machine

1. Single screw extruders by different screw / barrel designs and process arrangements for the most varied thermoplastic materials, increasing production reliability.

2. Compact design includes integrated PLC computer control system.

3. High performance transmission with torque reserves, good melt quality with a low-pulsation material transportation.

4. Length measuring system, pneumatic saw blade advance vertically upward, saw hood with integrated clamping above the cutting table or parallel guidance of the oscillating top belt / caterpillar at the front side, etc, the downstream equipment is easily adjusting and operating. Profile length is in a narrow tolerances.

5. Long operating life of screw and barrel.

6. Reduction of pump wear, noise reduction and low energy consumption.

7. Low maintenance and repair costs.

8. Customized designing requirement is welcome.

Optional Equipment

- Dosing System.

- Mixer.

- Feeding System.

- Winder Unit.

- Ink Jet System.

- Embossing System.

- Film Application.

- Printing System.

- UV Coating Unit.

- Punching Unit.

- Processing Equipment.

Application

1. Rigid PVC, Soft PVC, PE, PP, ABS, PC, PS, PET Profile.

2. Electrical Duct, Trunking Profile.

3. Foam Profile.

4. Window, door, blinder, building profile.

5. PC LED Light cover profile

- Decking, Fence, Wall, folding, Celling, flooring.

- Decoration Profile.

- Gasket, Edge Band, Refrigerator Profile.

- Window Roofing Profile.

6. Foam TPE wood-alike, no wood, profile.

7. Wood-Plastics-Composite, PP, PE, PVC, ABS, PC, PS, PA, PMMA profile.

Digital control of components and actual monitoring of production processes and quality, which also means that we are always close to the needs of customers.

Twin Screw Profile Extrusion Line | Plastic Profile Extrusion Solutions | Intype

Located in Taiwan since 1963, Intype Enterprise Co., Ltd. is a high efficiency plastic extrusion machines manufacturer. Their main plastic extrusion machines include, Twin Screw Profile Extrusion Line, sustainable plastic extrusions, continuous bead foam machines, supercritical reaction pelletizers, medical tube extrusion lines and profile extrusion machinery. Their offerings also encompass medical tube extrusion lines and profile extrusion systems. Intype is committed to innovation, quality, and environmental sustainability, focusing on efficient, eco-friendly technologies.

Discover Intype's advanced Plastic Extrusion Machines, a blend of innovation and 60 years of expertise. Specializing in TPE Wood-like Profiles, Continuous Bead Foam, and Supercritical Reaction Pelletizing, our machines are designed for efficiency and sustainability. Ideal for B2B buyers in the plastic extrusion industry, our products range from Medical Tube Extrusion Lines to Profile Extrusion and Recycling Solutions. Intype machines are synonymous with quality, precision, and eco-friendliness, ensuring optimal performance and environmental responsibility. Join the forefront of plastic extrusion technology with Intype's reliable and advanced solutions.

Intype has been providing customers with high efficiency plastic extrusion machines since 1963, with both advanced technology and 50 years of experience, Intype ensures that each customer's requirements are met.