Intype akan berpartisipasi dalam K Show 2022

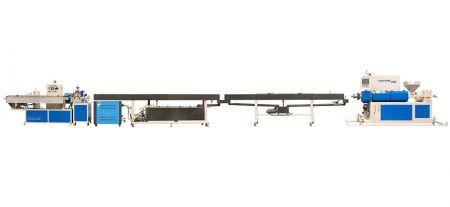

Intype Enterprise CO.,LTD. akan berpartisipasi dalam pameran "Dusseldorf Rubber & Plastics Exhibition (K Show)" yang diselenggarakan di Pusat Pameran Dusseldorf, Jerman, mulai tanggal 19 hingga 26 Oktober 2022. Konsultan-konsultan di stan akan menyediakan Anda dengan sejumlah layanan: "Pengenalan mesin ekstrusi Intype, layanan pemrograman jalur produksi, konsultasi solusi...dll". Intype berfokus pada penelitian dan pengembangan mesin ekstrusi plastik yang berkelanjutan, baik itu pipa dan tabung serbaguna, film tiup, profil, pencampuran / daur ulang pelet, atau pengembangan bahan baru yang inovatif - pelet dan profil imitasi kayu TPE, garis tabung medis berkecepatan tinggi dan kapasitas tinggi, biodegradable dan bioplastik, ekstrusi busa polimer berbutir kontinu, mesin ekstrusi Intype dapat mencapainya. Selamat datang untuk mengisi formulir di bagian bawah halaman ini untuk membuat janji selama pertunjukan, Intype siap melayani Anda.

K 2022 akan diselenggarakan dari 19 Oktober hingga 26 Oktober 2022, di Düsseldorf, Jerman untuk yang kedua puluh dua kalinya. K adalah pameran perdagangan terbesar di dunia untuk industri plastik dan karet. Acara ini mengumpulkan pemasok terpenting mesin plastik dan karet, bahan baku dan bahan tambahan, produk setengah jadi, suku cadang teknis, dan produk plastik yang diperkuat di bawah satu atap. Ini adalah platform yang ideal untuk memamerkan produk dan inovasi serta menjalin kontak bisnis.

Detail Pameran

- Tanggal: 19 Oktober ~ 26 Oktober 2022

- Nomor Booth: Hall 12 / C02-11

- Produk Terkait

- Aplikasi

Kontrol digital komponen dan pemantauan aktual proses produksi dan kualitas, yang juga berarti bahwa kami selalu dekat dengan kebutuhan pelanggan.

Intype akan berpartisipasi dalam K Show 2022| Solusi Ekstrusi Profil Plastik | Intype

Berlokasi di Taiwan sejak tahun 1963, Intype Enterprise Co., Ltd. adalah produsen mesin ekstrusi plastik yang efisien tinggi. Mesin ekstrusi plastik utama mereka termasuk ekstrusi plastik yang berkelanjutan, mesin busa bead kontinu, pelletizer reaksi superkritis, garis ekstrusi tabung medis, dan mesin ekstrusi profil. Penawaran mereka juga mencakup garis ekstrusi tabung medis dan sistem ekstrusi profil. Intype berkomitmen pada inovasi, kualitas, dan keberlanjutan lingkungan, dengan fokus pada teknologi yang efisien dan ramah lingkungan.

Temukan Mesin Ekstrusi Plastik Intype yang canggih, kombinasi inovasi dan pengalaman selama 60 tahun. Kami mengkhususkan diri dalam Profil Kayu TPE, Busa Bead Kontinu, dan Pelletisasi Reaksi Supercritical, mesin kami dirancang untuk efisiensi dan keberlanjutan. Ideal untuk pembeli B2B di industri ekstrusi plastik, produk kami meliputi Jalur Ekstrusi Tabung Medis hingga Solusi Ekstrusi Profil dan Daur Ulang. Mesin Intype identik dengan kualitas, presisi, dan ramah lingkungan, menjamin kinerja optimal dan tanggung jawab lingkungan. Bergabunglah dengan teknologi ekstrusi plastik terdepan dengan solusi yang handal dan canggih dari Intype.

Intype telah menyediakan mesin ekstrusi plastik yang efisien tinggi kepada pelanggan sejak tahun 1963, dengan teknologi canggih dan pengalaman selama 50 tahun, Intype memastikan bahwa setiap kebutuhan pelanggan terpenuhi.