เวียดนามพลาส 2022

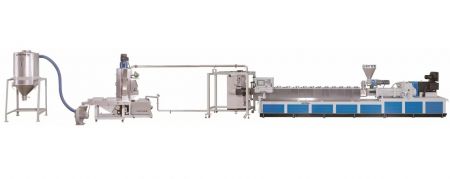

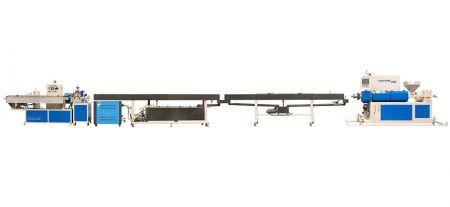

บริษัท Intype Enterprise จำกัด จะเข้าร่วมงาน "The 20th Vietnam Int’l Plastic & Rubber Industry Exhibition" ที่จัดขึ้นที่ศูนย์แสดงสินค้าและประชุมสมุทรสาคร ในเมืองโฮจิมินห์ ประเทศเวียดนาม ตั้งแต่วันที่ 23 ถึง 26 พฤศจิกายน พ.ศ. 2565. ที่ปรึกษาในบูธจะให้บริการหลายบริการให้คุณ เช่น "การแนะนำเครื่องอัด Intype เครื่อง, บริการโปรแกรมเส้นผลิต, การปรึกษาแนวทางการแก้ปัญหา... เป็นต้น". Intype มุ่งเน้นการวิจัยและพัฒนาเครื่องจักรการอัดเลเซอร์พลาสติกที่ยั่งยืน ไม่ว่าจะเป็นท่อและท่อทั่วไป ฟิล์มพลาสติกที่พัด โปรไฟล์ การผสม/การรีไซเคิลเพล็ตไลซิ่ง หรือการพัฒนาวัสดุใหม่ที่สร้างสรรค์ - เม็ดพลาสติกแบบไม้เทียม TPE และโปรไฟล์ที่คล้ายไม้ ไลน์ท่อแพทย์ที่มีความเร็วสูงและความจุสูง พลาสติกที่สามารถย่อยสลายและเป็นชีวภาพ การอัดเลเซอร์โพลิเมอร์บีดต่อเนื่อง Intype สามารถทำได้ ยินดีต้อนรับที่จะกรอกแบบฟอร์มที่ด้านล่างของหน้านี้เพื่อทำการนัดหมายในระหว่างการแสดง, Intype กำลังรอให้บริการคุณ

นิทรรศการอุตสาหกรรมพลาสติกและยางระหว่างประเทศเวียดนามครั้งที่ 20

ผู้จัดงานของ “งานแสดงสินค้าอุตสาหกรรมพลาสติกและยางระหว่างประเทศเวียดนามครั้งที่ 20” คือ กระทรวงอุตสาหกรรมและการค้า - บริษัท วินเอ็กซ์แอด นาชนิตและการประชาสัมพันธ์ จำกัด (วินเอ็กซ์แอด); บริษัท ยอร์เกอร์ส เทรดและการตลาด เซอร์วิส จำกัด.. ลาก่อนการแสดงสินค้าปี 2019 ครั้งสุดท้าย มีพื้นที่แสดงสินค้า 4 พื้นที่ มีบูธมากกว่า 800 บูธ และมีผู้จัดแสดงสินค้าและบริษัทมากกว่า 580 รายเข้าร่วมงานอย่างยิ่งใหญ่ สิ่งของที่จัดแสดงคือเครื่องจักรการเกลี่ยงานพลาสติกและยาง เครื่องจักรการอัดเส้นพลาสติก เครื่องฉีดพลาสติก เครื่องจักรการพิมพ์พลาสติกว่าง เครื่องจักรการบรรจุภัณฑ์ เครื่องจักรการรีไซเคิลพลาสติกและยาง เป็นต้น มีอุปกรณ์มากถึง 200 ชิ้นที่ถูกนำเสนอในสถานที่และผู้จัดแสดงจาก 18 ประเทศที่นำเสนออย่างยิ่งใหญ่ พื้นที่แสดงสินค้ารวมทั้งหมด 18,000 ตารางเมตร และมีผู้ซื้อทั้งหมด 15,231 คนเข้าเยี่ยมชม เพิ่มขึ้น 20%

รายละเอียดการแสดงสินค้า

- วันที่: 23 ถึง 26 พฤศจิกายน 2022

- บูธเลขที่: HALL A - A 303

- สถานที่: ศูนย์แสดงสินค้าและประชุมฯ สาธารณรัฐเวียดนาม จังหวัดโฮจิมินห์ ประเทศเวียดนาม

- ผลิตภัณฑ์ที่เกี่ยวข้อง

- การใช้งาน

ควบคุมดิจิตอลของส่วนประกอบและการตรวจสอบการผลิตและคุณภาพจริง ซึ่งหมายความว่าเราอยู่ใกล้กับความต้องการของลูกค้าเสมอ

เวียดนามพลาส 2022 | โซลูชันการอัดเม็ดพลาสติก | Intype

ตั้งอยู่ในไต้หวันตั้งแต่ปี 1963, Intype Enterprise Co., Ltd. เป็นผู้ผลิตเครื่องจักรอัดพลาสติกที่มีประสิทธิภาพสูง เครื่องจักรพลาสติกสำคัญของพวกเขาประกอบด้วยเครื่องจักรพลาสติกที่ยั่งยืน, เครื่องจักรโฟมบีดต่อเนื่อง, เครื่องจักรเม็ดประกอบออกซิเจนเชิงสร้างสรรค์, เครื่องจักรอัดสายทางการแพทย์และเครื่องจักรอัดโปรไฟล์ ผลิตภัณฑ์ของพวกเขายังรวมถึงเครื่องจักรสายท่อทางการแพทย์และระบบการอัดเส้นโครง Intype มุ่งมั่นที่จะสร้างนวัตกรรม คุณภาพ และการอนุรักษ์สิ่งแวดล้อม โดยเน้นเทคโนโลยีที่มีประสิทธิภาพและเป็นมิตรต่อสิ่งแวดล้อม

ค้นพบเครื่องจักรการอัดพลาสติกขั้นสูงของ Intype ผสมผสานนวัตกรรมและความเชี่ยวชาญที่มีมาเป็นเวลา 60 ปี เชี่ยวชาญในโปรไฟล์ที่คล้ายไม้ TPE, โฟมบีดต่อเนื่อง และการเปลี่ยนสภาวะเซอร์เปอร์คริติคอลเป็นเม็ดพลอยที่มีประสิทธิภาพและยั่งยืน เครื่องจักรของเราถูกออกแบบให้มีประสิทธิภาพและยั่งยืน เหมาะสำหรับผู้ซื้อธุรกิจระหว่างองค์กรในอุตสาหกรรมการอัดพลาสติกของเรา สินค้าของเราครอบคลุมตั้งแต่เครื่องอัดท่อทางการแพทย์ไปจนถึงเครื่องอัดโปรไฟล์และสิ่งที่เกี่ยวข้องกับการรีไซเคิล เครื่อง Intype เป็นเครื่องที่เชื่อมโยงกับคุณภาพ ความแม่นยำ และความเป็นมิตรต่อสิ่งแวดล้อม ทำให้มีประสิทธิภาพสูงสุดและรับผิดชอบต่อสิ่งแวดล้อม เข้าร่วมทางด้านหน้าของเทคโนโลยีการอัดพลาสติกด้วยโซลูชันที่เชื่อถือได้และทันสมัยของ Intype

Intype ได้ให้บริการเครื่องอัดพลาสติกที่มีประสิทธิภาพสูงให้กับลูกค้าตั้งแต่ปี 1963 ด้วยเทคโนโลยีที่ทันสมัยและประสบการณ์กว่า 50 ปี Intype รับประกันว่าจะตอบสนองความต้องการของลูกค้าแต่ละราย