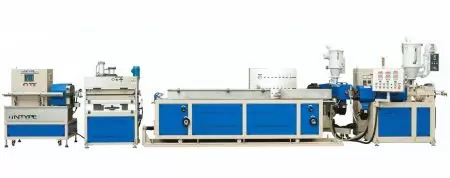

Foam TPE (100% NON Wood) Wood-Imitation Pelletizing and Profile Lines

Use of patented pelletizing machine design with copolymer foaming technology, foaming TPE to create a unique composited material. And then through our dedicated profile extrusion equipment to continuous produce a variety of finished and semi-finished products.

According to different customers' requirements, can change profile die to make different sizes and shapes, also can adjust machine operating parameter or material formula to change various hardness, densities and colors for diverse application.

In the process of extrusion production, it can naturally produce wood-texture look and wood-like touch, for different product applications, also can do secondary processing, like surface printing / embossing / pasting … etc.

Extrusion machine can be custom-made and design according to customer demands, optional include:

● The whole line adopts PLC HMI control system.

● Via Modbus, Profibus communication mode linking whole plant equipment.

● Production webcam and associated outputs data linking to the office LAN or through the Ethernet network for machine remote monitoring.

● Machine is designed to meet CE / UL standard.

● Full range of the machine can adopt one-stop design, including online punching and cutting / online printing / online embossing.

Applications

1. Furnishings and House Fittings.

2. Outdoor Side-walk, Fence and Railing, Building Block.

3. Bathroom and Humidity Areas Application.

4. Gardening and Horticulture Application.

5. Could be Used In Frigid and Torrid Zones, Environmental Temperature is between -30°C ~ 85°C.

Photo Gallerys

- Profile Application For Reference

- Profile Application For Reference

- Profile Application For Reference

- Profile Application For Reference

- Profile Application For Reference

- Profile Application For Reference

- Profile Application For Reference

- Profile Application For Reference

- Related Products

Digital control of components and actual monitoring of production processes and quality, which also means that we are always close to the needs of customers.

Foam TPE (100% NON Wood) Wood-Imitation Pelletizing and Profile Lines | High Efficiency Foam TPE Extruders | Intype

Located in Taiwan since 1963, Intype Enterprise Co., Ltd. is a high efficiency plastic extrusion machines manufacturer. Their main plastic extrusion machines include, sustainable plastic extrusions, continuous bead foam machines, supercritical reaction pelletizers, medical tube extrusion lines and profile extrusion machinery. Their offerings also encompass medical tube extrusion lines and profile extrusion systems. Intype is committed to innovation, quality, and environmental sustainability, focusing on efficient, eco-friendly technologies.

Discover Intype's advanced Plastic Extrusion Machines, a blend of innovation and 60 years of expertise. Specializing in TPE Wood-like Profiles, Continuous Bead Foam, and Supercritical Reaction Pelletizing, our machines are designed for efficiency and sustainability. Ideal for B2B buyers in the plastic extrusion industry, our products range from Medical Tube Extrusion Lines to Profile Extrusion and Recycling Solutions. Intype machines are synonymous with quality, precision, and eco-friendliness, ensuring optimal performance and environmental responsibility. Join the forefront of plastic extrusion technology with Intype's reliable and advanced solutions.

Intype has been providing customers with high efficiency plastic extrusion machines since 1963, with both advanced technology and 50 years of experience, Intype ensures that each customer's requirements are met.