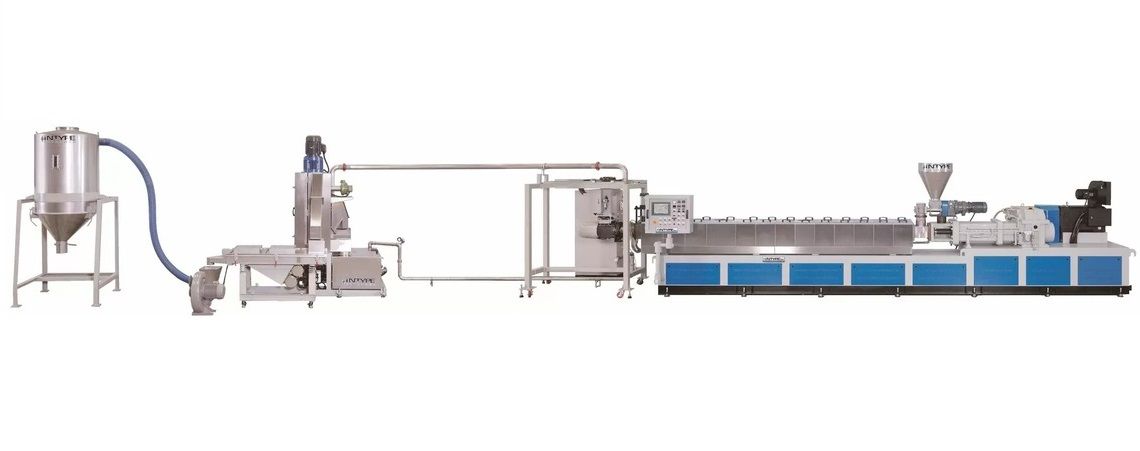

Continuous Bead Foaming Extrusion Equipment

CEG

Improvement in Foaming Production Method - Continuous Bead Foaming Replaces Batch Foaming

The traditional batch foaming manufacture, which uses foam bucket as batch production, the process is simple, but the production is time-consuming, and also in low capacity, it has been unable to supply the industry to quantify long term production, thus resulting in relatively high costs to the finished products.

The application of supercritical continuous bead foaming extrusion technology, its on line continue fast production bringing economic efficiency is the best way to replace the batch foaming manufacture.

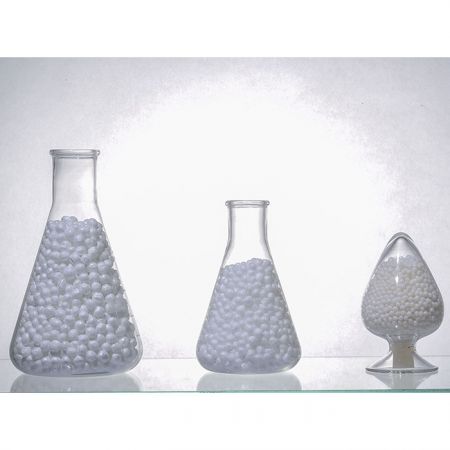

Advantageous Properties of Polymer Foamed Bead

Lightweight : Low density, high specific strength, its strength increases with the increasing of density, and can absorb the impact, with cushioning and load bearing capacity.

Also with the properties as compressible, flexible, electrical insulation, sound absorption, shock absorption, heat insulation, lower dielectric constant than the matrix resin, and provide porous contact surface... etc.

It's easy to secondary molding processing, and also easy to be glued, has become a rend in plastic processing. In industrial and even in daily life, its applications are really quite extensive.

Optional Equipment

- Pulverize Machine.

- High Speed Mixer & High Speed Cool Churning M/C.

- Feeding & Storage System.

- Raw Material Conveying System.

- Dosing System.

- Air Compressor.

- Chiller Cooling System.

- Storage System.

- Vent System.

- Vibration Unit.

- Bagging & Packaging & Weighing System.

- Material Convey System.

Application

1. Automotive and Aerospace Industry: Due to small foam cells, the foaming components will reduce the weight of the material, this lightweight property will reach energy efficiency, and also shockproof, shock absorbing and high specific strength are welcome advantageous properties for this industry.

2. Food Packaging: Reduces the use of packaging material and also reduces transportation costs. With low thermal conductivity is suitable for thermal insulation of food containers or fish boxes.

3. Buffer / Filling Package: Foaming material will absorb the impact, for use in packaging protection materials to reduce damage to finished products.

4. Sport and Fitness Equipment: With properties of lightweight and cushioning, high shock absorption and also good resilience, such as for shoe bottom application.

5. Fiber Industry: Excellent heat insulation, breathable perspiration.

6. Structural Material: The honeycomb structure of the porous body can shield electromagnetic waves, also is the best heat insulation material, available in the light mask, breathable cabinets....tec. Foam material is also because of high strength, and low com.

7. Composites Material: Special light, high strength, with resistance to impact, suitable for SMC, BMC, sandwich foam composites panel.

8. Medicine Biomaterial: Supercritical biodegradable material is suitable for artificial skin, artificial bone, clad material, drug release carrier.

9. Porous Carrier: Carrier for catalyst, ion exchange resin, drug,....etc.

Digital control of components and actual monitoring of production processes and quality, which also means that we are always close to the needs of customers.

Continuous Bead Foaming Extrusion Equipment | Plastic Profile Extrusion Solutions | Intype

Located in Taiwan since 1963, Intype Enterprise Co., Ltd. is a high efficiency plastic extrusion machines manufacturer. Their main plastic extrusion machines include, Continuous Bead Foaming Extrusion Equipment, sustainable plastic extrusions, continuous bead foam machines, supercritical reaction pelletizers, medical tube extrusion lines and profile extrusion machinery. Their offerings also encompass medical tube extrusion lines and profile extrusion systems. Intype is committed to innovation, quality, and environmental sustainability, focusing on efficient, eco-friendly technologies.

Discover Intype's advanced Plastic Extrusion Machines, a blend of innovation and 60 years of expertise. Specializing in TPE Wood-like Profiles, Continuous Bead Foam, and Supercritical Reaction Pelletizing, our machines are designed for efficiency and sustainability. Ideal for B2B buyers in the plastic extrusion industry, our products range from Medical Tube Extrusion Lines to Profile Extrusion and Recycling Solutions. Intype machines are synonymous with quality, precision, and eco-friendliness, ensuring optimal performance and environmental responsibility. Join the forefront of plastic extrusion technology with Intype's reliable and advanced solutions.

Intype has been providing customers with high efficiency plastic extrusion machines since 1963, with both advanced technology and 50 years of experience, Intype ensures that each customer's requirements are met.