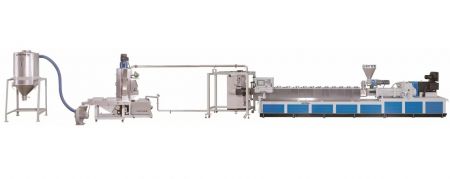

Compounding Pelletizing Extrusion Machine

Starch / PLA / Foam TPE / PP / PE / PVC / WPC / PET / PC / ABS / EVA Master Batch / Compounding / Pelletizing Extrusion Machine Line

Due to raw material insufficient performance or the recycled materials with larger decline in physical character and not suitable to produce of high-grade products. To improve the basic physical character of plastic materials, and fulfill the quality requirement of product, using modification processing for plastic to meet or exceed the performance of the original plastic.

We are able to offer the world market a wide range of machinery for pelletizing. Our single-screw extruders can process various plastics material with high output rates, it's ideal for compounding, coloring, and recycling, masterbatch. Twin-screw extruders are designed to efficiently and economically process, its maximum flexibility for plastic compounding and multipurpose processing is able to meet highest technical standards.

For optimization of processing, the control system is important to guarantee consistent production quality, we use PLC computer controller for automation control of the line. Over the past years, we have been successfully engaged in Underwater Pelletizer System, as well as cooperated with Japan company to develop Supercritical Reactive Compounding Pelletizing System, their high efficiency and performance are exceeding the traditional strand pelletizer and face cutting such pelletizer systems.

In order to operate under optimum function, upstream and downstream equipment is designed for the best matched with the extrusion line under many decades of experience. User's design is always available upon request for various application.

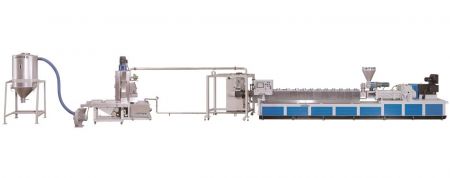

Extrusion Machines We Build

- Compounding / Coloring / Masterbatch / Recycling Pelletizing.

- Two- Stage, Strand, Die Face Cutting, Water Ring, Underwater Systems.

- Multi-Application Laboratory Type Pelletizer.

- Supercritical Reactive Compounding and Pelletizer System.

- Continuous Foaming.

Digital control of components and actual monitoring of production processes and quality, which also means that we are always close to the needs of customers.

Compounding Pelletizing Extrusion Machine | Bioplastic Extrusion Technology | Intype

Located in Taiwan since 1963, Intype Enterprise Co., Ltd. is a high efficiency plastic extrusion machines manufacturer. Their main plastic extrusion machines include, Compounding Pelletizing Extrusion Machine, sustainable plastic extrusions, continuous bead foam machines, supercritical reaction pelletizers, medical tube extrusion lines and profile extrusion machinery. Their offerings also encompass medical tube extrusion lines and profile extrusion systems. Intype is committed to innovation, quality, and environmental sustainability, focusing on efficient, eco-friendly technologies.

Discover Intype's advanced Plastic Extrusion Machines, a blend of innovation and 60 years of expertise. Specializing in TPE Wood-like Profiles, Continuous Bead Foam, and Supercritical Reaction Pelletizing, our machines are designed for efficiency and sustainability. Ideal for B2B buyers in the plastic extrusion industry, our products range from Medical Tube Extrusion Lines to Profile Extrusion and Recycling Solutions. Intype machines are synonymous with quality, precision, and eco-friendliness, ensuring optimal performance and environmental responsibility. Join the forefront of plastic extrusion technology with Intype's reliable and advanced solutions.

Intype has been providing customers with high efficiency plastic extrusion machines since 1963, with both advanced technology and 50 years of experience, Intype ensures that each customer's requirements are met.